Hot Stamping Body in White Market Size, Dynamics and Opportunity, Analysis by Forecast 2032

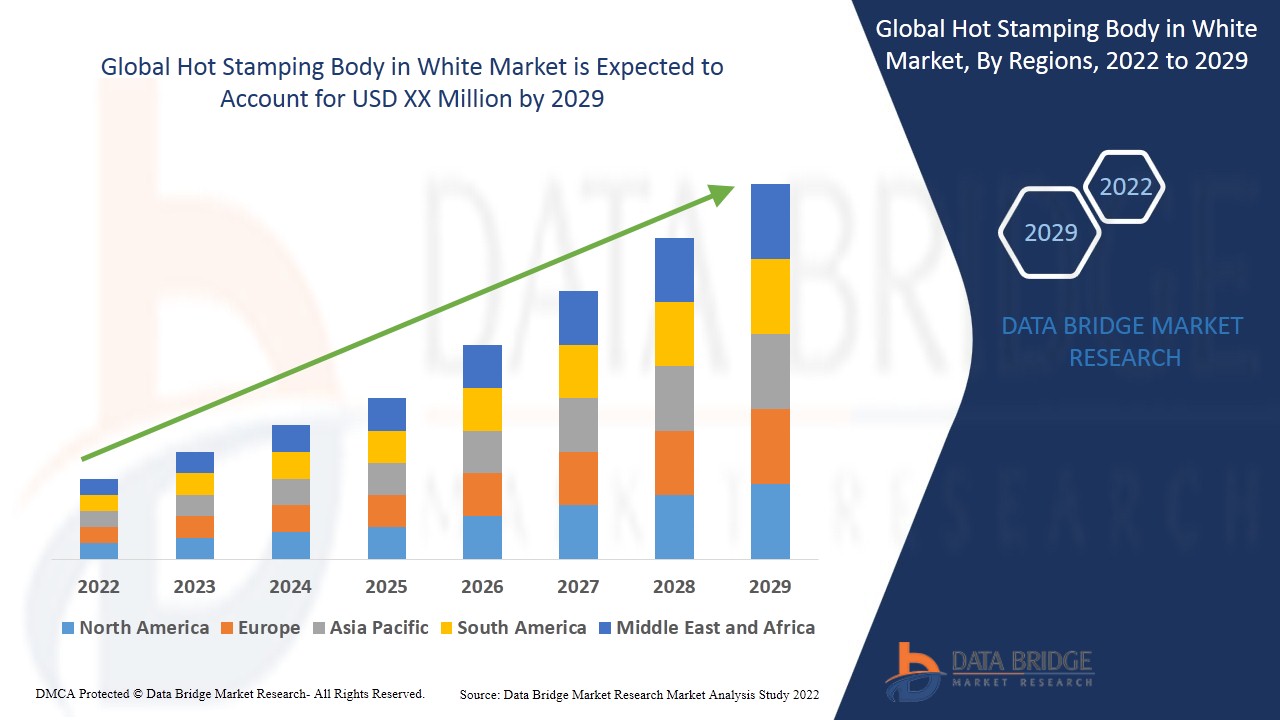

Data Bridge Market Research analyses that the hot stamping body in white market would exhibit a CAGR of 3.10% for the forecast period.

Introduction

The automotive industry is constantly evolving, with manufacturers seeking advanced materials and technologies to improve vehicle performance, safety, and efficiency. Among the many innovations in this space, hot stamping technology has gained significant traction, particularly in the production of body in white (BIW) components. The hot stamping body in white market is growing as automakers emphasize lightweight materials, fuel efficiency, and compliance with increasingly stringent safety and environmental regulations. BIW refers to the stage in automobile manufacturing where a car body’s sheet metal components are welded together before painting or assembly. Integrating hot stamping into this stage allows for the creation of complex and high-strength parts, ensuring better crash performance while reducing overall vehicle weight.

The rise of electric vehicles, stricter emissions standards, and consumer demand for durable, safe, and lightweight vehicles have all contributed to the increasing use of hot stamping in BIW applications. This article explores the market dynamics, key drivers, challenges, opportunities, regional insights, and competitive landscape of the hot stamping body in white market.

Market Overview

Hot stamping, also known as press hardening, involves heating sheet steel and stamping it into desired shapes at high temperatures. Once formed, the steel is rapidly cooled, which increases its tensile strength. This process is particularly important in producing automotive BIW parts such as pillars, roof rails, bumpers, and side impact beams. With the rise of lightweighting trends, hot stamping helps automakers achieve strength-to-weight optimization without compromising safety.

In recent years, automakers have increasingly integrated ultra-high-strength steels into vehicle structures. Hot stamping is a critical enabler of this shift, providing the durability required for safety-critical components while reducing vehicle weight to improve fuel efficiency and extend electric vehicle battery range. The technology has also expanded beyond traditional passenger cars to commercial vehicles, luxury cars, and electric mobility platforms.

Market Drivers

One of the primary drivers of the hot stamping BIW market is the growing demand for lighter vehicles that deliver improved fuel efficiency and reduced emissions. Hot stamping allows manufacturers to use thinner steel sheets without compromising structural integrity, thus reducing vehicle weight. The rapid adoption of electric vehicles has also accelerated demand, as automakers look for ways to extend battery performance by using lightweight materials.

Stricter safety and emission regulations worldwide are further pushing manufacturers toward hot stamping, since it enables stronger, crash-resistant vehicle components. Additionally, the expansion of automotive production in emerging economies is creating opportunities for wider adoption of hot stamping technology.

Market Challenges

Despite its advantages, hot stamping faces some challenges. The process requires significant investment in specialized equipment, which raises production costs and limits adoption by smaller manufacturers. The manufacturing process itself is complex, involving precise heating and cooling cycles that require skilled labor and strict quality control systems.

Competition from alternative lightweight materials such as aluminum and carbon fiber is another challenge, especially in luxury and high-performance vehicles where cost is less of a constraint. These alternatives sometimes offer better weight reduction, but hot stamping remains more cost-effective for mass production.

Opportunities

The ongoing growth of electric and hybrid vehicles offers major opportunities for the hot stamping BIW market. As automakers continue to balance safety, durability, and lightweighting, hot stamping is well positioned to play a central role. The integration of new advanced steels, such as third-generation high-strength steels, will further expand the scope of the technology.

The adoption of Industry 4.0, automation, and digitalization in automotive manufacturing also opens opportunities to enhance hot stamping efficiency, reduce costs, and scale production more effectively.

Regional Insights

Asia-Pacific is currently the fastest-growing region in the hot stamping BIW market, driven by large-scale automotive production and strong government initiatives promoting cleaner and safer vehicles. Europe remains a key market due to strict environmental regulations and the presence of premium automotive manufacturers. North America is experiencing increasing adoption as automakers shift production toward electric vehicles. Latin America and the Middle East & Africa are smaller markets but are expected to grow steadily with rising automotive investments.

Competitive Landscape

The market is highly competitive, with global and regional players investing heavily in research and development, capacity expansion, and collaborations with automakers. Key companies are focusing on enhancing efficiency, developing new hot stamping techniques, and integrating advanced steel grades to strengthen their market position. Some of the prominent players include Gestamp Automoción, ArcelorMittal, Thyssenkrupp, Voestalpine, and Magna International.

Future Outlook

The future of the hot stamping body in white market is closely tied to the transformation of the global automotive industry. As electrification, sustainability, and safety continue to dominate industry priorities, hot stamping will remain a core technology for achieving lightweight and durable vehicle structures. Advances in materials, manufacturing automation, and global expansion of automotive production will further drive the adoption of hot stamping across markets.

FAQs

What are the main applications of hot stamping in body in white manufacturing?

How does hot stamping technology contribute to the growth of electric vehicles?

What are the biggest challenges faced by manufacturers in adopting hot stamping?

Which regions are expected to lead the growth of the hot stamping BIW market?

Who are the leading companies operating in this market?

Equip yourself with actionable insights and trends from our complete Hot Stamping Body in White Market analysis. Download now:https://www.databridgemarketresearch.com/reports/global-hot-stamping-body-in-white-market

Browse More Reports:

Global Pulp Moulding Tooling Market

Global Pump Jack Market

Global Purine Analogues Drugs Market

Global Quad Flat Package (QFP) Microcontroller Socket Market

Global Quality Grading and Inspection Services Market

Global Quinolones Market

Global Radar Transmitter Market

Global Radio Immunoassay (RIA) Reagents and Devices Market

Global Ranitidine Market

Global Rathke's Cleft Cyst Market

Global Razor Market

Global Reconditioned Steel Drum Market

Global Recycled Lead Market

Global Recycled Styrenics Market

Global Reed Sensor Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 1022

Email:- corporatesales@databridgemarketresearch.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness