Parts of a Transformer – The Power Inside That Keeps Everything Running

Have you ever paused and thought about what really goes on inside those giant metal boxes humming quietly near your house or factory? Those silent beasts are transformers — the lifeline of electrical distribution. But behind that calm buzz lies a world of precision, insulation, and engineering brilliance built by real experts like KE Core Electric.

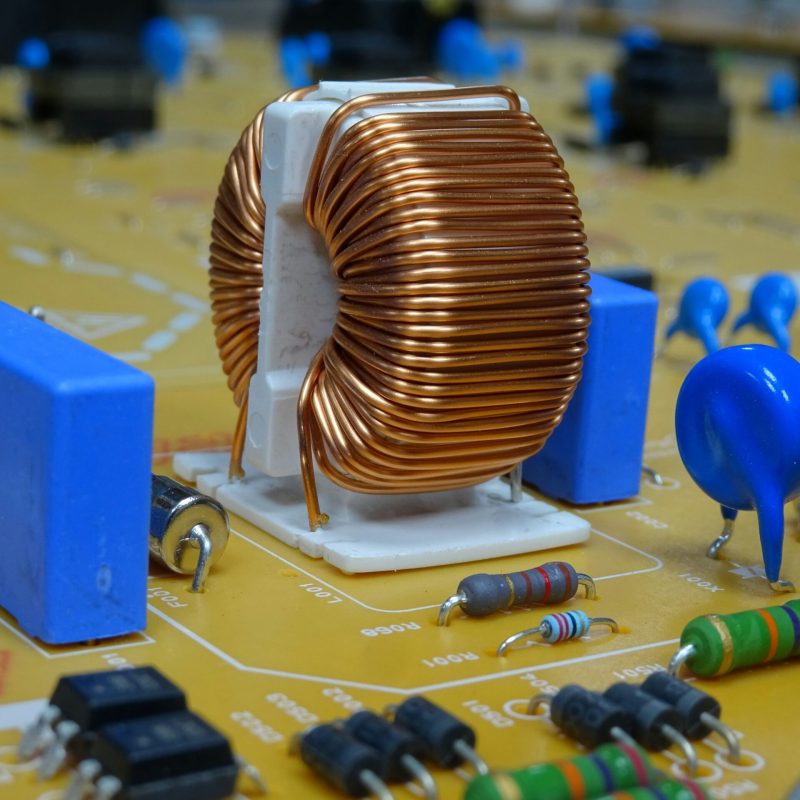

Understanding the Heart of a Transformer

When we talk about the Parts of a Transformer, we’re not just talking about copper wires or steel tanks. It’s much deeper — every single layer, every insulation sheet, and even the bolts play a role in keeping power stable, safe and efficient.

A transformer is basically made up of two main sections:

-

The Magnetic Core – where all the magnetic flux magic happens.

-

The Windings – coils that actually carry the electric current.

But the story doesn’t end there. The unsung hero is the insulation system that protects, supports, and separates these parts. That’s where the real craftsmanship of companies like KE CORE ELECTRIC PRIVATE LIMITED comes into play.

Why Insulation Is Everything

Imagine a transformer without insulation — it would literally burn out in seconds. The insulation keeps different voltage levels apart, prevents short circuits, and extends the life of the entire equipment.

Key insulation materials include:

-

Densified laminated wood – strong, oil-resistant, and dimensionally stable.

-

Pre-compress pressboard – perfect for creating spacers, rings, cylinders and other mechanical supports.

Both of these materials are crucial in transformer manufacturing and maintenance. KE Core Electric uses them to craft components that not only meet standards but exceed expectations.

Meet the Experts: Transformer Insulation Parts Specialists

Behind every reliable power transformer, there’s a team of specialists ensuring precision at every stage. Transformer Insulation Parts Specialists like those at KE CORE ELECTRIC PRIVATE LIMITED have decades of combined knowledge and experience.

They don’t just cut boards or press wood — they engineer protection. Their role includes:

-

Designing customized insulation layouts

-

Choosing proper grades of materials

-

Ensuring dielectric and mechanical integrity

-

Testing under extreme load and temperature

When industries depend on uninterrupted power, they depend on people who know their transformer inside and out — just like KE Core Electric.

Deep Dive Into Transformer Components

Each of the Transformer Parts has a specific purpose — no element is decorative or optional. Let’s break it down.

1. Core

The backbone of every transformer. It’s made of laminated sheets of high-grade silicon steel that reduce eddy currents and minimize losses.

2. Windings

The copper or aluminum conductors wound around the core. There’s a high-voltage (HV) and low-voltage (LV) side — both insulated meticulously.

3. Insulating Materials

Where Pre-compress pressboard and Densified laminated wood shine. They are used to build spacers, supports, and barriers that maintain dielectric strength.

4. Oil & Cooling System

The oil acts as both an insulator and a coolant. It transfers heat from windings to radiators or tanks, maintaining temperature balance.

5. Bushings, Conservator & Breather

Bushings allow safe current passage through grounded walls. The conservator tank compensates for oil expansion, while the breather keeps moisture out.

How KE Core Electric Keeps the Standard High

At KE Core Electric, every insulation part is made with absolute precision — whether it’s for a 100 kVA distribution transformer or a 500 MVA power transformer. Their focus is not only on performance but also on consistency and safety.

A few highlights of their craftsmanship:

-

Customized machining for specific transformer models

-

Vacuum drying processes for moisture removal

-

Sustainable sourcing of insulation-grade wood

-

Quick delivery and strict quality assurance

They believe the small details — a perfect edge finish, the right thickness, the exact fit — make a huge difference when the transformer is running under real load conditions.

The Subtle Art of Transformer Insulation

People often overlook insulation as just another layer. But, in reality, it’s a critical component that decides the life span of the transformer.

Here’s why:

-

Thermal Endurance – withstands high temperatures for years.

-

Electrical Strength – resists voltage breakdown and flashover.

-

Mechanical Stability – holds the windings firmly under magnetic forces.

Densified laminated wood provides structural support while Pre-compress pressboard ensures high dielectric strength — together, they create the perfect insulating balance.

Challenges in the Field

Even experts like KE CORE ELECTRIC PRIVATE LIMITED face challenges such as:

-

Variation in raw material quality

-

Moisture absorption during humid climates

-

Maintaining tight tolerances during machining

But with advanced processes, testing, and decades of practical experience, they continue to deliver components that stand up to the harshest industrial demands.

Conclusion: Powering the Future with Precision

Transformers may look silent, but the engineering inside them speaks volumes about human innovation and dedication.

The Parts of a Transformer and its insulation system form the invisible foundation of modern power systems.

And companies like KE Core Electric — true Transformer Insulation Parts Specialists — ensure that this foundation remains strong for generations.

Their use of Densified laminated wood and Pre-compress pressboard shows their commitment to quality, safety, and reliability.

In the end, when the lights stay on and machines hum perfectly — it’s not magic.

It’s the hard work, precision, and integrity of people who understand transformers inside out.

That’s what makes KE Core Electric more than just a manufacturer — it makes them a trusted partner in powering the world.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness