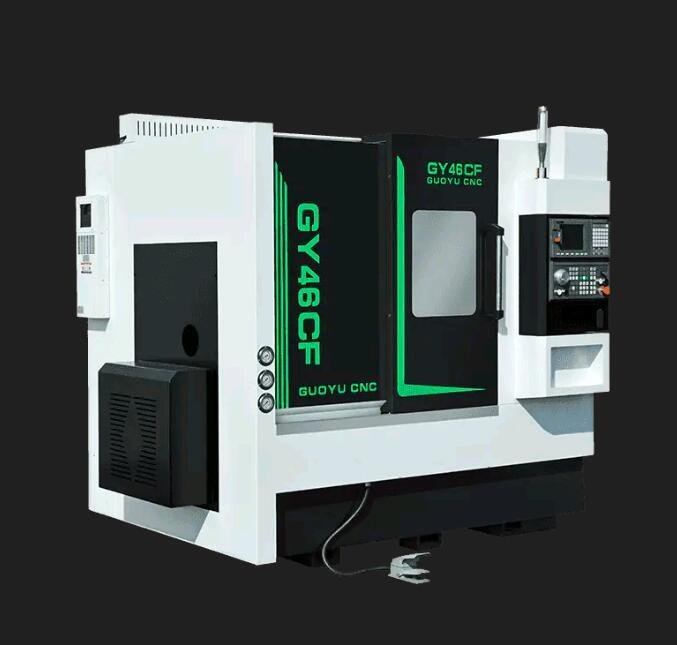

Linear Rail CNC Machines: Enhancing Precision and Speed in Machining

A Linear Rail CNC machine is a sophisticated piece of equipment used in manufacturing and precision machining processes. These machines are built with advanced linear rail systems that enable smooth, accurate, and efficient movement of the machine's components. Ideal for industries that require high precision, such as aerospace, automotive, and metalworking, a linear rail CNC machine combines automation with precision to deliver consistent results.

The primary feature of a linear rail CNC machine is its ability to provide exceptional precision. The linear rails guide the moving parts of the machine with minimal friction, ensuring smooth motion along the X, Y, and Z axes. This results in high accuracy during cutting, milling, or drilling operations. The precise movement is ideal for producing parts that require tight tolerances and intricate designs.

Linear rail CNC machines are built to last, with the linear rails made from high-quality materials such as stainless steel or hardened steel. These materials resist wear and tear, ensuring the machine maintains its performance over time. Additionally, linear rail systems often come with sealed bearings and lubrication systems, which help reduce maintenance needs and extend the lifespan of the machine.

The use of linear rails ensures that the machine operates smoothly, even at high speeds. The reduced friction between moving components allows for faster and quieter operation. This smooth motion minimizes the risk of vibration, contributing to better surface finishes and more accurate machining results.

Linear rail CNC machines are designed to handle heavier loads compared to traditional machines. This feature allows for the machining of larger, heavier workpieces with stability, increasing the versatility of the machine for different applications.

https://www.zjgycnc.com/product/milling-turning-multifunctional-cnc-machine/

45° slant bed base structure, with strict aging treatment, smooth chip removal, and reasonable cutting space.

Independent sleeve type spindle unit imported angular contact spindle bearing, and through precise dynamic balance, the spindle rotates stably at high speed.

Wide precision linear guideway and center precision ball screws are adopted to enhance the overall rigidity and accuracy retention of the machine tool.

Widened T-type middle slide plate, which is convenient for installing gang-type tools, horizontal turrets, and live tool units.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness