How Foil Direct’s Self-Adhesive Plotter Films Simplify Application

For sign-makers, designers, and DIY enthusiasts alike, the moment of truth arrives when a carefully crafted design must be transferred from the plotter to its final surface. This application process can be fraught with potential for error, from misalignment to frustrating air bubbles. Foil Direct’s self-adhesive plotterfolien are engineered specifically to transform this critical stage from a high-pressure task into a smooth, manageable, and successful experience. Their unique construction and user-focused features work in concert to simplify every step, ensuring professional results are accessible to everyone.

The Built-In Guide: Precision Kiss-Cutting

The foundation of a simple application lies in the precision of the cut. Foil Direct’s films are designed for flawless kiss-cutting, where the plotter blade cleanly slices through the coloured foil and adhesive layers but intentionally leaves the clear polyester carrier sheet intact. This creates a built-in stencil or guide for the installer. The entire design remains perfectly positioned on the carrier sheet, holding even the most intricate elements—like fine text or delicate logos—in their exact place. This eliminates the guesswork and frustration of handling dozens of tiny, individual pieces, allowing you to work with the design as a single, cohesive unit.

Bubble-Free Bonding with Engineered Adhesives

The adhesive on the back of these films is a marvel of formulation. It’s not just a sticky layer; it’s a pressure-sensitive adhesive engineered for controlled application. This technology provides two key benefits. First, it offers initial, low-tack adhesion. This means you can position the film on the surface and, if needed, carefully lift and reposition it without stretching the material or leaving residue behind. Second, once firmly pressed into place, the adhesive forms a permanent, bubble-free bond that grows stronger over time. This forgiving nature removes the anxiety of a "one-shot" placement, making the process far less stressful.

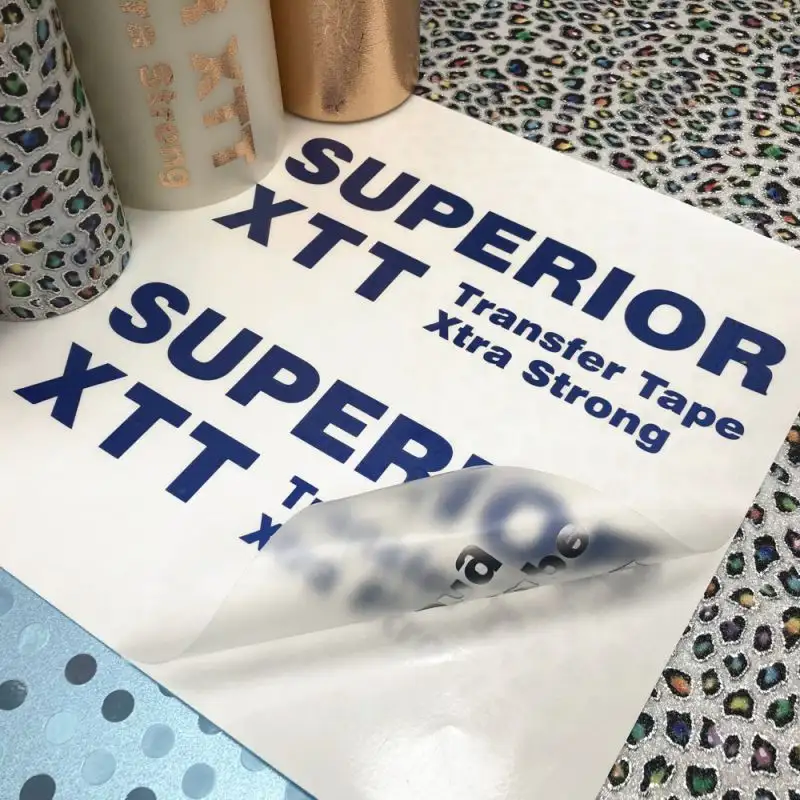

The Invisible Assistant: Application Tape Integration

Foil Direct integrates high-quality application tape directly over the cut design during the manufacturing process. This semi-transparent, low-tack tape acts as your handle and transfer mechanism. It’s strong enough to lift the entire design off the wax-backed liner paper and hold it together during manipulation, yet its adhesive is precisely calibrated to release the foil graphic easily once it’s pressed onto the final surface. This seamless integration means you don’t have to source or apply your own transfer tape, saving time and ensuring perfect compatibility with the foil film.

Effortless Alignment and Repositioning

Thanks to the initial low-tack of the adhesive and the stability provided by the application tape, aligning your design becomes a straightforward task. You can hold the graphic up to the surface, adjust its position left or right, and lower it gently to check for perfect placement. The film will lightly stick, allowing you to peel it back and readjust if it’s not quite straight. This repositionability is a game-changer for applying multi-part designs or ensuring that a large graphic is perfectly centred on a window or wall, drastically reducing the risk of a crooked final result.

A Streamlined Path from Weeding to Installation

The process flow is intuitively streamlined. After the design is cut, you move to weeding—removing the excess foil from around your desired graphic. Because the kiss-cut is so clean, this step is smooth and precise. Once weeded, the application tape is already in place, so you simply move to mounting. There’s no need for additional tools or steps between weeding and application. This seamless transition not only saves time but also minimizes the chance of the design being accidentally disturbed or contaminated before it’s applied.

Conquering Complex Shapes and Fine Details

Perhaps the most significant simplification occurs with complex graphics. Applying a detailed logo with thin lines and small text using traditional methods can be nearly impossible. With Foil Direct’s system, these challenging elements are held securely by the application tape. You apply the entire intricate design in one smooth motion, rather than struggling with tiny, fragile pieces. This capability empowers users to tackle ambitious projects with confidence, knowing the material is working with them to secure every minute detail until the very last moment.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness