GV Mold: Revolutionizing Plastic Molded Components through Material Choices

GV Mold has established itself as a pioneer in the plastic injection molding industry by placing a strong emphasis on material selection. This focus has allowed the company to revolutionize the production of plastic molded components across various sectors, including home appliances, automotive, electronic goods, and industrial applications. By leveraging their expertise in material science and manufacturing processes, GV Mold ensures that each product not only meets but exceeds client expectations in terms of functionality, durability, and cost-effectiveness.

The Science Behind Material Selection

At the heart of GV Mold's success lies a deep understanding of material properties and their impact on final products. The company's team of experts carefully evaluates each project's requirements, considering factors such as strength, flexibility, temperature resistance, custom plastic injection molding and chemical compatibility. This meticulous approach ensures that the chosen material aligns perfectly with the intended application, whether it's a wear-resistant component for industrial machinery or a food-safe container for household use.

Tailoring Solutions for Diverse Industries

GV Mold's expertise in material selection allows them to cater to a wide range of industries with specialized needs. In the automotive sector, for instance, the company might opt for lightweight yet durable materials that contribute to fuel efficiency without compromising on safety. For electronic goods, materials with excellent electrical insulation properties are prioritized. This industry-specific approach demonstrates GV Mold's commitment to delivering tailored solutions that address unique challenges across different sectors.

Balancing Performance and Sustainability

In today's environmentally conscious market, GV Mold recognizes the importance of sustainable practices. The company actively explores and implements eco-friendly material options that maintain high performance standards while reducing environmental impact. This might include the use of recycled plastics or biodegradable polymers for appropriate applications. By striking a balance between performance and sustainability, GV Mold helps clients meet their environmental goals without sacrificing product quality.

Enhancing Product Lifecycle Through Material Innovation

Material selection plays a crucial role in determining a product's lifecycle. GV Mold leverages its expertise to choose materials that not only meet immediate performance requirements but also contribute to long-term durability and reliability. This foresight in material selection can lead to products with extended lifespans, reduced maintenance needs, and improved overall value for end-users. Whether it's a high-stress industrial component or a consumer product subject to daily wear and tear, GV Mold's material choices aim to maximize product longevity.

Optimizing Manufacturing Processes

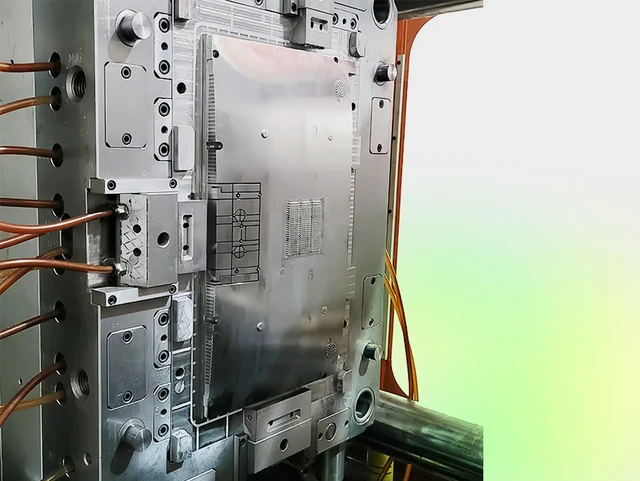

The right material choice can significantly impact manufacturing efficiency. GV Mold's approach to material selection takes into account factors such as mold flow characteristics, cooling rates, and post-molding properties. By choosing materials that are well-suited to the injection molding process, the company can optimize production cycles, reduce defects, and minimize waste. This not only leads to cost savings but also ensures consistent quality across large production runs.

Collaborative Approach to Material Selection

GV Mold believes in the power of collaboration when it comes to material selection. The company actively engages with clients and suppliers through their Early Supplier Involvement (ESI) program, fostering an environment where expertise from various stakeholders can contribute to the decision-making process. This collaborative approach often leads to innovative material solutions that might not have been considered otherwise, pushing the boundaries of what's possible in plastic injection molding.

GV Mold's commitment to revolutionizing plastic molded components through strategic material choices sets them apart in the industry. By combining scientific knowledge with practical manufacturing expertise, the company continues to deliver products that meet the evolving needs of diverse industries. As we look towards the future, GV Mold's innovative approach to material selection promises to drive further advancements in plastic injection molding, offering clients cutting-edge solutions that balance performance, sustainability, and cost-effectiveness.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness